What is the Role of Packaging Robots in Modern Manufacturing Processes

In the rapidly evolving landscape of modern manufacturing, the integration of technology plays a crucial role in enhancing efficiency and productivity. One of the most transformative innovations in this sector is the advent of packaging robots. These sophisticated machines have revolutionized the way products are packed, allowing manufacturers to streamline their processes while ensuring consistency and quality. As industries strive to meet the demands of an increasingly competitive market, the implementation of packaging robots is becoming not just an advantage but a necessity.

Packaging robots are designed to automate the packing process, reducing the reliance on manual labor and minimizing human error. By employing advanced technologies such as artificial intelligence and machine learning, these robots can adapt to various packaging tasks, managing everything from high-speed assembly to intricate packing designs. This flexibility not only enhances production speed but also allows manufacturers to respond swiftly to changing market needs. Furthermore, the use of packaging robots contributes significantly to operational safety, alleviating workers from repetitive tasks and potentially hazardous environments.

As manufacturers look to optimize their operations, understanding the role of packaging robots becomes essential. Their impact extends beyond mere efficiency gains; they represent a shift towards smarter, more agile manufacturing practices. By delving into the various applications and benefits of packaging robots, we can appreciate how they are reshaping the manufacturing landscape and paving the way for a more innovative future.

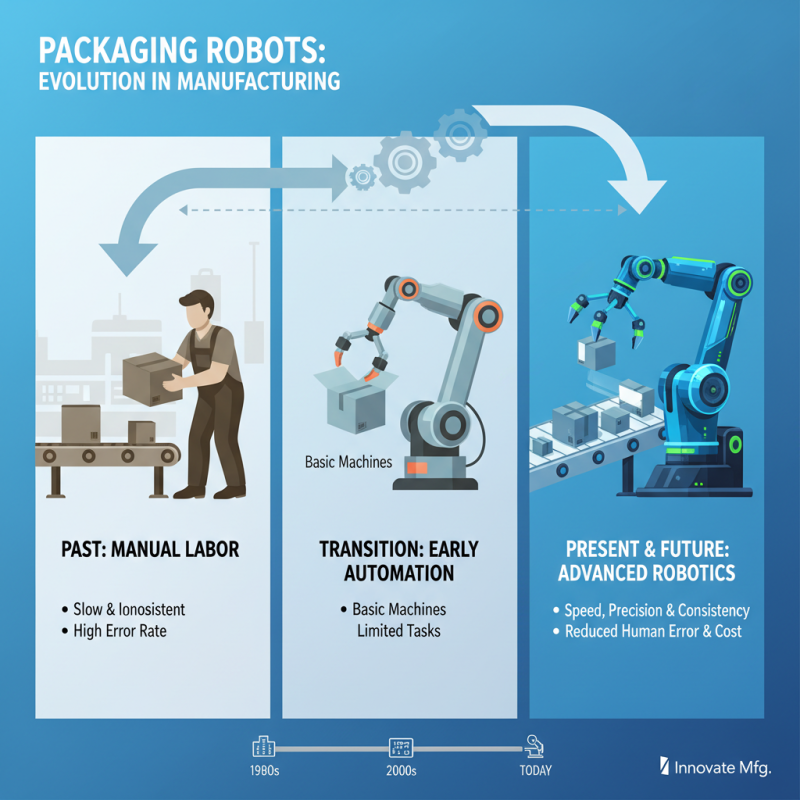

The Evolution of Packaging Robots in Manufacturing Industries

The evolution of packaging robots in manufacturing industries has been remarkable, reflecting the broader technological advancements in automation and robotics. Initially, packaging processes were labor-intensive, relying heavily on manual labor to handle tasks such as boxing, wrapping, and labeling products. However, as manufacturing demands increased and efficiency became paramount, companies began integrating robotic solutions into their operations. This transition not only enhanced speed and consistency but also reduced human error, leading to significant improvements in productivity.

Over the years, packaging robots have advanced from basic mechanical arms performing repetitive tasks to sophisticated systems equipped with artificial intelligence and machine learning capabilities. These modern robots can now adapt to varying product sizes and shapes, handle fragile items with care, and even perform quality control checks. The integration of advanced sensors and vision systems allows these robots to operate seamlessly alongside human workers, optimizing workflows and ensuring a higher standard of output. As industries continue to evolve, the role of packaging robots becomes increasingly vital, paving the way for smarter, more efficient manufacturing processes.

Key Technologies Driving the Adoption of Packaging Robots

The adoption of packaging robots in modern manufacturing processes is significantly influenced by several key technologies. One of the primary drivers is the advancement in artificial intelligence (AI) and machine learning. These technologies enable robots to learn from their environment, improve their efficiency, and adapt to varying packaging requirements.

AI algorithms analyze production data in real-time, allowing robots to make quick decisions on the packaging line, such as adjusting to different product shapes or sizes without the need for manual reconfiguration.

Another crucial technology is the integration of Internet of Things (IoT) capabilities within packaging robots. IoT enables seamless communication between robots and other machinery on the production line, facilitating enhanced coordination and productivity. This connectivity allows for predictive maintenance, where sensors monitor the robots' health and performance, potentially addressing issues before they lead to downtime. Furthermore, IoT-driven analytics provide insights into operations, allowing manufacturers to optimize workflows and resource allocation, thereby increasing the overall efficiency of the packaging process.

Lastly, advancements in robotic dexterity and sensors have greatly enhanced the capability of packaging robots. Modern robots can handle delicate items with precision and speed, significantly reducing the risk of product damage during packaging. Enhanced vision systems and tactile sensors enable robots to distinguish between different product types and packaging materials, ensuring proper handling. This combination of improved flexibility and intelligence plays a crucial role in meeting the growing demands of various industries, paving the way for a more automated and efficient manufacturing landscape.

Impact of Packaging Robots on Production Efficiency Metrics

Packaging robots play a crucial role in enhancing the efficiency of modern manufacturing processes. By automating the packaging workflow, these robots significantly reduce the time taken for product handling and packing, thereby streamlining operations. Their precision and speed surpass that of human workers, leading to higher throughput rates. In environments where rapid product turnover is essential, the ability of packaging robots to work continuously without fatigue ensures that production lines maintain a steady pace, minimizing bottlenecks.

The impact of packaging robots extends beyond mere speed; they also contribute to improved accuracy and consistency in packaging processes. This reduction in packaging errors not only enhances the quality of the final product but also decreases waste and rework costs. Furthermore, with advanced sensing and adaptive capabilities, these robots can easily adjust to handle different product shapes and sizes, making them versatile assets in any manufacturing setup. As a result, companies can achieve better production efficiency metrics, such as reduced cycle times and lower operational costs, ultimately leading to enhanced competitiveness in the market.

Cost-Benefit Analysis of Implementing Packaging Robots

The implementation of packaging robots in modern manufacturing processes can significantly enhance operational efficiency and reduce long-term costs. One primary advantage is the reduction in labor costs. By automating repetitive packaging tasks, companies can minimize the reliance on manual labor, leading to significant savings in salary expenses, employee benefits, and associated training costs. Furthermore, robots work continuously without fatigue, allowing for increased output and consistency in packaging quality, which can translate to fewer defects and returns.

In addition to labor savings, the cost-benefit analysis of packaging robots takes into account the initial investment versus the potential long-term savings. While the upfront costs of acquiring and integrating robotic systems may seem substantial, these costs are often offset by the enhanced productivity and efficiency gained over time. Automated packaging processes can also lead to optimized material usage, reducing waste and improving sustainability metrics. Thus, even with maintenance and operational costs factored in, businesses can achieve a favorable return on investment, making packaging robots a financially sound choice in the landscape of modern manufacturing.

What is the Role of Packaging Robots in Modern Manufacturing Processes - Cost-Benefit Analysis of Implementing Packaging Robots

| Dimension | Details |

|---|---|

| Initial Investment | $100,000 - $500,000 |

| Expected Lifespan | 10 - 15 years |

| Labor Cost Savings | 20% - 30% |

| Production Efficiency Increase | 15% - 50% |

| Space Requirement | 200 - 1,500 sq. ft. |

| Return on Investment (ROI) | 5 - 10 years |

| Impact on Product Quality | Consistent and Reduced Errors |

| Market Trends | Growth of 10% per year |

Future Trends in Packaging Robotics and Automation Integration

The integration of automation in packaging robotics is rapidly reshaping manufacturing processes, emphasizing efficiency and precision. Future trends indicate a significant push towards the adoption of artificial intelligence and machine learning technologies, which will enhance the capabilities of packaging robots. These intelligent systems will not only automate repetitive tasks but also adapt to changes in production demands, making real-time adjustments to workflows. The increased use of sensors and IoT devices will further facilitate seamless communication between machines, leading to optimized operations and reduced downtime.

Moreover, the trend towards sustainability is driving advancements in packaging robotics. Manufacturers are seeking eco-friendly materials and processes, which packaging robots can help implement efficiently. Automation will support the creation of smarter, more flexible packaging solutions that minimize waste while maintaining product integrity. The collaboration between robots and human workers will also evolve, with exoskeletons and collaborative robots assisting in flexible packaging lines, promoting a more dynamic manufacturing environment. This synergy will not only enhance productivity but also improve workplace safety, paving the way for a future where automation and human ingenuity work hand in hand.

Related Posts

-

Revolutionizing Efficiency: The Future of Packaging Robots in Smart Warehousing

-

Why Robotics Engineering is the Future of Innovation and Technology

-

Exploring the Future of Robotics Engineering in Everyday Life

-

10 Proven Benefits of Robotic Process Automation Software for Boosting Business Efficiency

-

Revolutionizing Logistics: How Warehouse Automation Robots are Shaping the Future of Supply Chains

-

How to Harness the Power of AI Robots for Everyday Tasks

Smart Robotics brand movie

Watch video